Zubkov A.G, Kuptsov A.I, Gimranov F.M. Modeling emptying equipment through reset with candle // International scientific review. – 2015. — №8 (9). – pp. 22-24.

Modeling emptying equipment through reset with candle

Моделирование опорожнения оборудования через сброс со свечи

Zubkov A.G., Kuptsov A.I., Gimranov F.M.

Зубков Алексей Геннадьевич / Zubkov Aleksej Gennad’evich – эксперт, ООО «Эксперт-92», г. Казань

Купцов Адель Игоревич / Kupcov Adel’ Igorevich – аспирант кафедры промышленной безопасности, Казанский национальный исследовательский технологический университет, г. Казань

Гимранов Фидаис Мубаракович / Gimranov Fidais Mubarakovich – профессор, доктор технических наук, заведующий кафедрой промышленной безопасности, Казанский национальный исследовательский технологический университет, г. Казань

Аннотация: Получены зависимости, которые позволяют определить параметры и граничные условия сброса со свечи, в зависимости от времени. Предлагается использовать результаты при численном моделировании нестационарного сброса газа через свечи.

Abstract: The dependences which allow defining parameters and boundary conditions of the reset with candle, depending on the time. It is proposed to use the results of the numerical modeling of unsteady reset gas through candles.

Ключевые слова: газ, опорожнение оборудования, сброс через свечи.

Keywords: gas, emptying equipment, reset with candle.

In the case of evacuation equipment at bus stops for repairs or in an emergency situation when you need to free it from circulating gases used device — blowing candles and candle dissipation. Typically, they are used for reset of light gases (methane, natural gas and hydrogen-containing gas with the ratio of the gas density and density of air no more than 0.8). The amount of gas released can be considerable, and accordingly, as the statistics show, in some cases, there is the formation of dangerous concentrations of gas-air mixture directly within industrial sites.

The greatest danger discharge explosive gases are as close to the reset with point, at industrial sites are burning torches, equipment with fire (eg, pyrolysis furnace, conversion, etc.) or other permanent sources of ignition [1].

To avoid exceeding the maximum allowable concentrations and lower flammability limits, in practice, carried out calculations: identify a safe distance from the candle to the areas of process units, define the required parameters and conditions reset with candle. For this purpose, stationary mathematical model known as the OND-86 [2], «Guidelines for safety flare systems» [3] and others.

These methods have several disadvantages: a fixed flow rate of gas and stationary atmospheric diffusion under actual conditions emptying equipment; no account of the terrain and the availability of technological objects in the zone of dangerous gases, etc. [4].

In this connection, the most suitable for studies of the processes of gas reset is the procedure of numerical simulation based on the classical conservation laws with the help of computer systems.

However, for adequate modeling of subsequent spread of air-gas mixture formed in the surface layer, it is necessary to lay the correct parameters and conditions reset with candle speed, pressure, temperature, density and compressibility of the reseted gas at the outlet of the candle, and the resulting throttling effect. It is the task of our research.

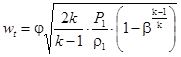

It is known that the gas velocity (m/s) discharged from the candle is determined by the formula Saint-Venant, assuming that the cross-sectional area substantially smaller candles sectional area equipment from which the gas is discharged:

, (1)

, (1)

where ![]() – adiabatic index;

– adiabatic index; ![]() – the gas pressure in the equipment, Pa;

– the gas pressure in the equipment, Pa;

![]() – gas density, kg / m3;

– gas density, kg / m3;

![]() – pressure ratio in atmosphere (Па) and equipment

– pressure ratio in atmosphere (Па) and equipment![]() , (

, (![]() )

)

![]() – flow coefficient, which depends on the hydraulic resistance of holes and shape holes candles.

– flow coefficient, which depends on the hydraulic resistance of holes and shape holes candles.

It is worth noting that increasing the pressure drop ![]() gas velocity

gas velocity ![]() increases only up to a maximum speed which is approximately equal to the speed of sound in the environment.

increases only up to a maximum speed which is approximately equal to the speed of sound in the environment.

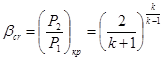

Critical pressure ratio ![]() , which corresponds to the maximum critical speed of gas flowing from the candle is defined as follows:

, which corresponds to the maximum critical speed of gas flowing from the candle is defined as follows:

. (2)

. (2)

But with increasing pressure ![]() above beyond the critical value, the actual velocity of the increase will not be. Therefore, when calculating the critical flow (

above beyond the critical value, the actual velocity of the increase will not be. Therefore, when calculating the critical flow (![]() ), in the formula (1) con:

), in the formula (1) con:

(3)

(3)

or, in the case of critical flow ( ![]() ):

):

![]() . (4)

. (4)

Thus, the critical velocity of the gas at the outlet of the candle will be approximately equal to the local speed of sound and can be represented as:

![]() .(5)

.(5)

The main initial conditions at the critical speed:

![]() ,(6)

,(6)

![]() .(7)

.(7)

The pressure as a function of time is presented below:

![]() . ( 8)

. ( 8)

In those cases when the pressure ratio reaches a critical value, the initial conditions are as follows:

These dependences can determine the parameters and conditions reset with candle, depending on the time and solve the problem of their jobs in the calculation of non-stationary reset gas through candles. Thanks to this adequately modeled by subsequent actual distribution of the gas mixture formed in the surface layer, it is possible to pre-calculate the safe distance from the candle to the areas of process units, define the required parameters and conditions reset with candle. Calculations by numerical modeling assumptions take into account the regulatory procedures in the future may be used for practical applications in gas resets from different candles.

References

1. Бесчастнов М., Соколов В. Предупреждение аварий в химических производствах. М.: Машиностроение, 1979 г., 392 с.

2. ОНД-86 «Методика расчета концентраций в атмосферном воздухе вредных веществ, содержащихся в выбросах предприятий»

3. «Руководство по безопасности факельным систем» (утверждено Приказом Ростехнадзора от 26.12.2012 № 779).

4. А.И. Купцов, Р.Р. Акберов, Д.Я. Исламхузин, Ф.М. Гимранов. Проблемы расчета рассеивания легких газов в атмосфере при их выбросах со свечи с учетом рельефа и застройки местности и атмосферной устойчивости // Научный журнал «Вестник Казанского технологического университета». №6. 2014. C. 284-286.

Свежие комментарии